Barangaroo (Sydney) skyline.

Barangaroo (Sydney) skyline.

In 1913, L. Messy O.E. addressed the Queensland Institute of Engineers with a paper he wrote titled, Reinforced Concrete. The paper featured in the Brisbane Courier on 17 June 1913 for its analysis of the benefits of this new method of construction.

Messy wrote:

In conclusion, I may be justified in quoting a resolution of the Congress of Civil Engineers in London which says:

“Reinforced concrete combines the structural qualities of steel and timber with the durability of good masonry. It is subject to no form of deterioration which cannot be avoided by reasonable precautions. It is free from many of the limitations surrounding the use of masonry in masses, because of the greater latitude it affords in the design and execution of structures. It often yields the best and most economical solution, and in some cases the only practical solution, of the most difficult problems. When properly designed and executed it is therefore among the most valuable, if not the most valuable material now available for use in connection with building and hydraulic works of all kinds.”

The same reasons Reinforced Concrete was touted as the most valuable building material over one hundred years ago still applies today.

Durable

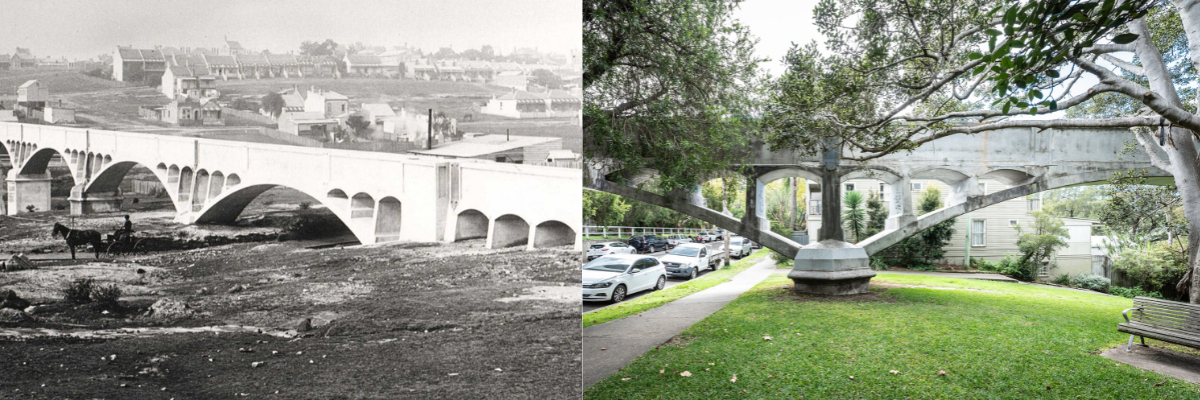

Durability is the #1 reason for why Australians choose reinforced concrete. Australia’s first reinforced concrete structure, Johnston’s Creek Sewer Aqueduct in Annandale (Sydney), was completed in 1896 to carry sewerage from the densely populated inner west suburbs of Balmain, Annandale and Glebe.

The 127-year-old aqueduct continues to serve the local community today.

Johnston’s Creek Sewer Aqueduct in 1896 and 2021.

Johnston’s Creek Sewer Aqueduct in 1896 and 2021.

In a country where almost 90% of the population live within 50km of the coast, Australian structures need to withstand highly exposed environments. Steel in concrete gives designers confidence that the structure will endure harsh weather conditions over the long term.

Consider the Sydney Opera House built in 1959. The reinforced concrete building sits on the water’s edge and continues to serve its original design intent after 64 years.

Sydney skyline with Sydney Opera House in foreground.

Sydney skyline with Sydney Opera House in foreground.

The properties of reinforced concrete contribute to it's resilience following natural disasters. Strength against cyclones and severe storms, impervious to water damage from floods, and resistance to hail, heatwaves, and fire (incombustible), makes reinforced concrete the safest method of construction.

Reinforced concrete Luna residences at Burleigh Heads. Designed by Plus Architecture and developed by Forme. (image: www.lunaburleigh.com.au)

Reinforced concrete Luna residences at Burleigh Heads. Designed by Plus Architecture and developed by Forme. (image: www.lunaburleigh.com.au)

Versatile

No other building material provides the design freedom like reinforced concrete.

The Tree House, located in Brisbane’s west end, demonstrates reinforced concrete’s compatibility with green building. The 13-storey ‘biophilic’ building comprises 90 apartments designed to increase occupant connectivity to the natural environment. Features include integration with Davies Park, which sits opposite the Tree House, mature trees planted on every balcony, a landscaped rooftop garden, and a curvaceous form that references the winding base of a fig tree.

Tree House by Aria in West End, Brisbane (image courtesy of McNab Builders)

Tree House by Aria in West End, Brisbane (image courtesy of McNab Builders)

Large open spaces are created through expansive column spacing. For example, the La Trobe reading room in the State Library of Victoria is almost 35m in diameter. When the library was built in 1913, it was the largest reinforced concrete dome in the world.

La Trobe Reading Room in State Library of Victoria (image courtesy of Wikipedia).

La Trobe Reading Room in State Library of Victoria (image courtesy of Wikipedia).

Monolithic structures and innovative shapes can be achieved with reinforced concrete because it can be: (1) moulded and formed in-situ, and (2) designed with no transport limitations. The Punchbowl Mosque in southwest Sydney, designed by Angelo Candalepas, was almost entirely cast in situ. The design brief called for a 300 - year life. Candalepas proposed 1,000 years!

Punchbowl Mosque, constructed in 2019 (Photograph: Brett Boardman)

Punchbowl Mosque, constructed in 2019 (Photograph: Brett Boardman)

Warm and aesthetically pleasing homes are designed in reinforced concrete.

Seidler House, the home of architects Harry and Penelope Seidler in Killara (Sydney), was built in 1967 and is constructed in reinforced concrete.

Harry & Penelope Seidler House, Killara, NSW 1967. Architects Harry & Penelope Seidler. (Photos: Max Dupain 1967 copyright Penelope Seidler.)

Harry & Penelope Seidler House, Killara, NSW 1967. Architects Harry & Penelope Seidler. (Photos: Max Dupain 1967 copyright Penelope Seidler.)

Our desire to create greater harmony among indoor and outdoor spaces in our homes makes reinforced concrete the perfect solution.

For example, the Concrete House (2019), designed by Matt Gibson Architecture in Melbourne, brings the outside in, and inside out.

Concrete House – Northern exposure. (Photo copyright Derek Swalwell)

Concrete House – Northern exposure. (Photo copyright Derek Swalwell)

Economical

No other building material can provide greater ‘lifetime’ value for money than reinforced concrete.

Steel reinforcement and concrete are produced at scale in Australia and distributed by competitive supply chains with stringent quality standards.

We have a highly skilled trade base for the design, production, transport, and construction of reinforced concrete structures. Hence, the speed of construction is unmatched by any other building material.

Australia 108, with golden starburst, under construction in Melbourne. At 317m, it is the 2nd tallest building in Australia after Q1 on the Gold Coast, which is 322m tall. (Photo courtesy Form700)

Australia 108, with golden starburst, under construction in Melbourne. At 317m, it is the 2nd tallest building in Australia after Q1 on the Gold Coast, which is 322m tall. (Photo courtesy Form700)

Minimal maintenance is another key factor for why reinforced concrete is cost efficient. It might need to be cleaned every 10 years or so, but you eliminate the costly problems of rot, mould, pests and rust that you might get with other materials.

Messi was prescient when he said:

“When properly designed and executed it [reinforced concrete] is therefore among the most valuable, if not the most valuable material now available for use in connection with building and hydraulic works of all kinds”.

His words continue to hold true today – over 100 years later.

But there’s one more benefit that was unlikely to be on people’s minds in the early 1900’s …

Sustainable

Steel is a 100% recyclable material, with no loss in material strength or quality.

Steel reinforcement in Australia is manufactured locally using recycled steel as a key part of our circular economy. This steel is produced in an electric arc furnace using electricity to melt the scrap metal. As our power supply transitions from fossil fuels to renewable sources, such as wind, solar, and hydrogen, steel will become increasingly sustainable.

Recycled scrap metal being collected by large magnets for production of new steel products at Rooty Hill Steel Mill (Sydney).

Recycled scrap metal being collected by large magnets for production of new steel products at Rooty Hill Steel Mill (Sydney).

Concrete is also a recyclable product. It is made from cement, water, sand, gravel, and crushed stone. Manufacturers have dramatically reduced carbon emissions from cement production by using supplementary cementitious materials such as fly ash and slag, waste by-products from power stations and steel making, respectively.

Low carbon products developed by the concrete industry can achieve cement reductions up to 50%. When these innovative products are combined with recycled aggregates, the CO2 emissions are reduced by 50 to 60 percent, with no loss of performance.

According to Norman Foster, of Fosters and Partners architecture firm, reinforced concrete structures are possibly the most sustainable because of their in-use performance.

"I think that there are a lot of dangerous myths about materials, recycling and sustainability. We had a very intense debate on this in the jury of the Stirling Prize [the biggest prize in UK architecture]. It wasn't about the material, it was about how you use that material,” Foster says.

He refers to the unique Apple Park headquarter building he designed in Cupertino, California.

"Not to underestimate the energy embodied in that process, but if you took the Apple building – the concrete structure is reinforced, so it's working structurally – obviously, nothing new. You're running small bore pipes through it, so you can channel hot or chilled water so it's eliminating all the traditional ductwork.

"So you're shrinking the height of that building. But you're maintaining the generous floor-to-ceiling height for the occupants, you're reducing the external envelope and the concrete is the finish – so you're not lining."

Apple Park headquarters, Cupertino, California. (Image: wikipedia)

Apple Park headquarters, Cupertino, California. (Image: wikipedia)

Another eco-friendly characteristic of reinforced concrete is its capacity to be adapted and repurposed.

When AMP decided that their Sydney office tower built in the 1970’s no longer suited their needs, they didn’t demolish the building and start again.

They repurposed it!

Quay Quarter Tower (QQT) reuses two-thirds of the existing reinforced concrete building and grafts onto existing slabs to double the square meters on site from 45,000 m² to 90,000 m².

“We made a commitment to make QQT Zero Carbon from Day 1 of operation”, said Chris Nunn, Head of Sustainability and Operations at AMP Capital.

“And we’re pleased to say we achieved that goal.”

Quay Quarter Tower (Sydney). (Photograph: Fred Holt.)

Quay Quarter Tower (Sydney). (Photograph: Fred Holt.)

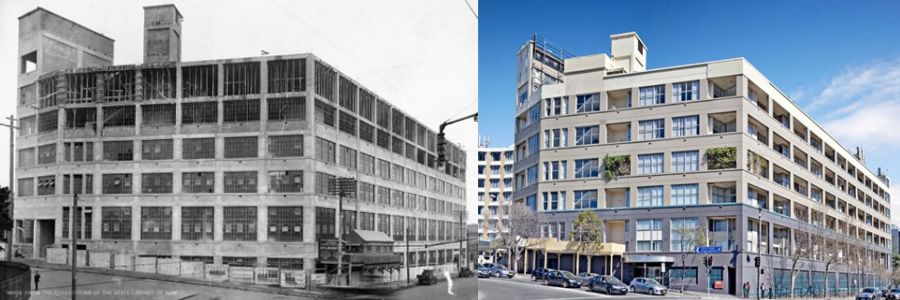

Another example of a repurposed reinforced concrete building is the Smith and Waddington Factory built in 1927. The building began life as a car assembly plant in Camperdown, Sydney. In 1993, the building was converted into 140+ apartments. The reinforced concrete structure was largely preserved, whilst the interior was completely reconfigured.

L - Smith and Waddington Factory, circa 1927. (Image from the collections of the State Library of NSW). R - Rhodes House apartments, circa 1993. (Image: realestate.com.au)

L - Smith and Waddington Factory, circa 1927. (Image from the collections of the State Library of NSW). R - Rhodes House apartments, circa 1993. (Image: realestate.com.au)

As Engineer John Woodside, who won a Medal of the Order of Australia last year for his contributions to Australia’s construction industry, put it:

“The most sustainable building is a recycled building”.

In fact, the true sustainability metric for a building material is total emissions divided by total life span.

With generations of potential lifespan, resilience to fire, water, and pests, freedom of design expression, and economical build process, reinforced concrete is the most sustainable material on the planet.

< Go Back